ISOBUS Functionaity

ISOBUS functionality allows the operator to control and monitor all aspects of the CCX 9010 from the tractor cab.

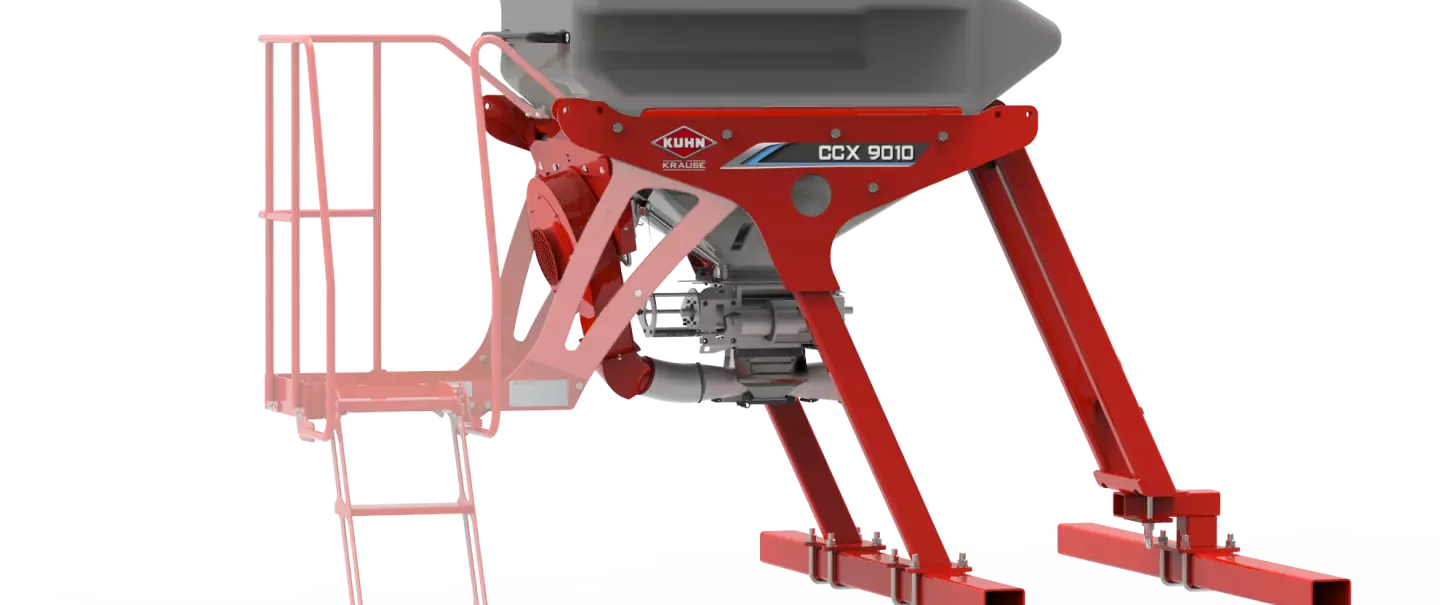

| Number of Diffusers |

|---|

| Max Hopper Width (A) |

| Min Vertical Height Required (B) (Not Including Attachment or Options) |

| Total Vertical Height (C) (Including Attachment, Not Including Options) |

| Min Length Required (D) (Not Including Attachment or Options) |

| Total Length (E) (Including Attachment, Not Including Options) |

| Recommended Clearance Below Meter (F) (Provided with Attachment) |

| Weight (Empty, without Adaptation) |

| Distance Between Mounting Tubes (G) |

| Dimensions of mounting tubes |

| CCX 9010-34 ACC | CCX 9010-45 ACC |

|---|---|

| Width Kits with 16, 20 or 24 Diffusers Available | Width Kits with 16, 20 or 24 Diffusers Available |

| 3'10" (1.1 m) | 4'8" (1.4 m) |

| 5'3" (1.4 m) | 5'3" (1.4 m) |

| 7'2" (2.2 m) | 7'3" (2.2 m) |

| 5'4" (1.6 m) | 5'4" (1.6 m) |

| 7'7" (2.3 m) | 6'10" (2.1 m) |

| 2'3" (0.7 m) | 2'3" (0.7 m) |

| 1,355 lb (615 kg) | 1,456 lb (660 kg) |

| 3'9" (1.1 m) | 3'6" (1.1 m) |

| 4" x 5" x 81" (10.1 cm x 12.7 x 205.7 cm) | 4" x 5" x 81" (10.1 cm x 12.7 x 205.7 cm) |

| Hopper Capacity |

|---|

| Metering Unit |

| Small Seed Splines |

| Speed Signal |

| Agitator Shaft |

| Control Terminal |

| Units Used |

| In-Cab Application Rate Adjustment |

| Automatic Start/Stop |

| Calibration Assistant |

| Area Meter |

| Filling Platform and Access Ladder |

| CCX 9010-34 ACC | CCX 9010-45 ACC |

|---|---|

| 27 Bushels / 34 ft³ / 963 Liters | 36 Bushels / 45 ft³ / 1274 Liters |

| Volumetric Metering Unit with Electric Drive | Volumetric Metering Unit with Electric Drive |

| Standard | Standard |

| From Tractor ISOBUS (Standard) or Using GPS Speed Sensor (Optional) | From Tractor ISOBUS (Standard) or Using GPS Speed Sensor (Optional) |

| Standard: Engaged / Disengaged without Wrenches | Standard: Engaged / Disengaged without Wrenches |

| Optional | Optional |

| User Defined: Imperial or Metric | User Defined: Imperial or Metric |

| Standard: Rate Can Be Adjusted To + / - 99% of Target Rate On The Fly | Standard: Rate Can Be Adjusted To + / - 99% of Target Rate On The Fly |

| Standard | Standard |

| Standard | Standard |

| Standard | Standard |

| Optional | Optional |

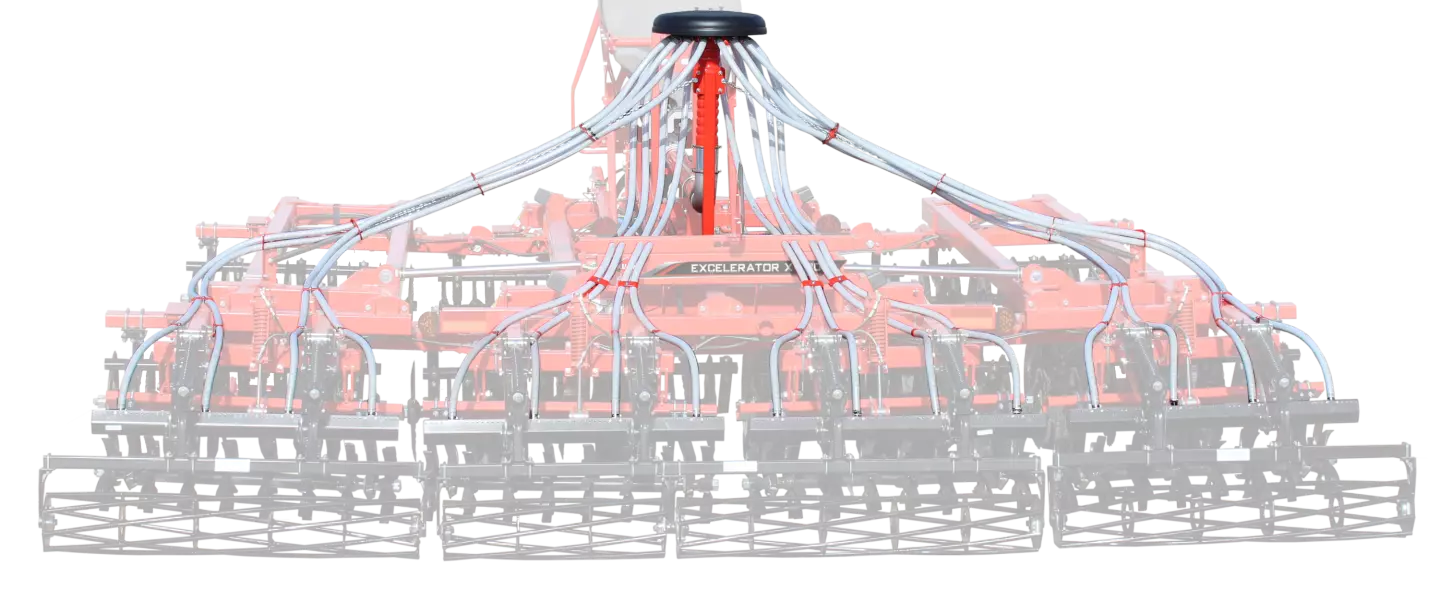

| Width Kit Options |

|---|

| 5" dia x 94" Steel Pipe to Space Divider Head Rearwards from Metering Unit |

| Brackets to Mount Diffusers to KUHN 24/7 Reel Systems |

| ISOBUS Terminal |

| ISOBUS Tractor Harness |

| GPS Speed Sensor |

| Third Party GPS Harness |

| CCX 9010-34 ACC | CCX 9010-45 ACC |

|---|---|

| < 10': 16 Diffusers / 125' Hose 10' - 15': 16 Diffusers / 175' Hose 15' - 20': 20 Diffusers / 225' Hose 20' - 30': 24 Diffusers / 400' Hose 30' - 35': 24 Diffusers / 450' Hose < 3.0m: 16 Diffusers / 38.1m Hose, 3.0m - 4.6m 16 Diffusers / 53.3m Hose, 4.6' - 6.1m: 20 Diffusers / 68.6m Hose, 6.1m - 9.1m: 24 Diffusers / 121.9m Hose, 9.1m - 10.7m: 24 Diffusers / 137.2m Hose | < 10': 16 Diffusers / 125' Hose 10' - 15': 16 Diffusers / 175' Hose 15' - 20': 20 Diffusers / 225' Hose 20' - 30': 24 Diffusers / 400' Hose 30' - 35': 24 Diffusers / 450' Hose < 3.0m: 16 Diffusers / 38.1m Hose, 3.0m - 4.6m 16 Diffusers / 53.3m Hose, 4.6' - 6.1m: 20 Diffusers / 68.6m Hose, 6.1m - 9.1m: 24 Diffusers / 121.9m Hose, 9.1m - 10.7m: 24 Diffusers / 137.2m Hose |

| Optional | Optional |

| Optional | Optional |

| CCI 800 or CCI 1200 Available as Option for Machines Equipped with CCX ISOBUS. Only Required if Customer Does Not Have Own Compatible ISOBUS Display, or Where Customer Wishes to Have a Second ISOBUS Display In-Cab. | CCI 800 or CCI 1200 Available as Option for Machines Equipped with CCX ISOBUS. Only Required if Customer Does Not Have Own Compatible ISOBUS Display, or Where Customer Wishes to Have a Second ISOBUS Display In-Cab. |

| ISOBUS Tractor Harness Available as Option for Machines Equipped with CCX ISOBUS. Only Required for Use with Non-ISOBUS Tractors | ISOBUS Tractor Harness Available as Option for Machines Equipped with CCX ISOBUS. Only Required for Use with Non-ISOBUS Tractors |

| GPS Speed Sensor Available as Option When ITH Harness is Selected. Only Required for Non-ISOBUS Tractors Where No Other ISOBUS Compatible Speed Source is Available. | GPS Speed Sensor Available as Option When ITH Harness is Selected. Only Required for Non-ISOBUS Tractors Where No Other ISOBUS Compatible Speed Source is Available. |

| GPS Speed Sensor Available as Option When ITH Harness is Selected. Only Required for Non-ISOBUS Tractors Where a Third Party GPS Unit Needs to be Connected to the KUHN ITH Harness. Note: Additional Cables May be Required from the GPS Manufacturer. | GPS Speed Sensor Available as Option When ITH Harness is Selected. Only Required for Non-ISOBUS Tractors Where a Third Party GPS Unit Needs to be Connected to the KUHN ITH Harness. Note: Additional Cables May be Required from the GPS Manufacturer. |

| Control box |

|---|

| Control box |

| CCX 9010-34 ACC | CCX 9010-45 ACC |

|---|---|

| 106761;194317 | 106761;194317 |

| 187348 | 187348 |