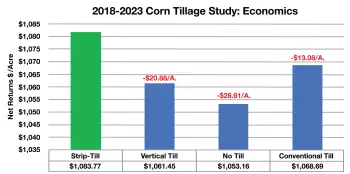

This chart illustrates 2018-2023 data from the PTI Farm. Strip-till over this period provided the highest overall net returns with conventional tillage behind by -$13.08/A. Vertical and no-till resulted in losses of -$20.33 and -$28.61/A.

This chart illustrates 2018-2023 data from the PTI Farm. Strip-till over this period provided the highest overall net returns with conventional tillage behind by -$13.08/A. Vertical and no-till resulted in losses of -$20.33 and -$28.61/A.

| Transport Width |

|---|

| Transport Height |

| Frame Type |

| Number of Row Units |

| Row Spacing |

| Working Width |

| Weight |

| 1210-830 | 1210-1230 | 1210-1630 |

|---|---|---|

| 12'4" (3.7 m) | 17'7" (5.4 m) | 17'7" (5.4 m) |

| 9'5" (2.9 m) | 11'6" (3.5 m) | 11'6" (3.5 m) |

| Folding | Folding | Folding |

| 8 | 12 | 16 |

| 30" (76 cm) | 30" (76 cm) | 30" (76 cm) |

| 20' (6.1 m) | 30' (9.1 m) | 40' (12.2 m) |

| 15,412 lb (6 991 kg) | 20,685 lb (9 374 kg) | 24,312 lb (11 030 kg) |

| Hitch Type |

|---|

| ST-PRO™ II Row Unit |

| Depth Control |

| Tire/Wheels |

| Transport Locks and Safety |

| 1210-830 | 1210-1230 | 1210-1630 |

|---|---|---|

| Power Pin AB Hitch CAT III | Power Pin AB Hitch CAT IV | Power Pin AB Hitch CAT IV |

| See Row Unit Specification Table (Below) for Additional information | See Row Unit Specification Table (Below) for Additional information | See Row Unit Specification Table (Below) for Additional information |

| Fixed Frame with Adjustable Shanks | Fixed Frame with Adjustable Shanks | Fixed Frame with Adjustable Shanks |

| Main Frame: Walking Tandem 445 Metric, 10-Bolt Hub. Replaceable Spindles | Main Frame: Walking Tandem 445 Metric, 10-Bolt Hub Wing Frame: 12-Row 280 Metric Single on each Wing. Replaceable Spindles | Main Frame: Walking Tandem 445 Metric, 10-Bolt Hub Wing Frame: 16-Row 280 Metric Duals on each Wing. Replaceable Spindles |

| Hydraulic Valves, Transport and Wind Fold, Slow Moving Vehicle Sign, Height Visibility LED Lighting | Hydraulic Valves, Transport and Wind Fold, Slow Moving Vehicle Sign, Height Visibility LED Lighting | Hydraulic Valves, Transport and Wind Fold, Slow Moving Vehicle Sign, Height Visibility LED Lighting |

| Frame Type |

|---|

| Liquid Fertilizer |

| Dry Fertilizer |

| Rear Hitch |

| 1210-830 | 1210-1230 | 1210-1630 |

|---|---|---|

| Integral 4-Bar Link Design | Integral 4-Bar Link Design | Integral 4-Bar Link Design |

| 1,000 Gallon Liquid Tank, Saddles and Wash Station | 1,000 Gallon Liquid Tank, Saddles and Wash Station | 1,000 Gallon Liquid Tank, Saddles and Wash Station |

| 6-Ton or 9-Ton Dry Fertilizer System from Montag Manufacturing | 6-Ton or 9-Ton Dry Fertilizer System from Montag Manufacturing | 6-Ton or 9-Ton Dry Fertilizer System from Montag Manufacturing |

| Liquid or NH3, Nurse Cart | Liquid or NH3, Nurse Cart | Liquid or NH3, Nurse Cart |

| Coulter |

|---|

| Row Cleaners |

| Shanks |

| Berm Conditioner |

| 1210-830 | 1210-1230 | 1210-1630 |

|---|---|---|

| 25", 6 Gauge | 25", 6 Gauge | 25", 6 Gauge |

| Floating 16" Notched Disc Blades | Floating 16" Notched Disc Blades | Floating 16" Notched Disc Blades |

| 5/8" x 4-7/16" Adjustable to 6" to 12" Depth | 5/8" x 4-7/16" Adjustable to 6" to 12" Depth | 5/8" x 4-7/16" Adjustable to 6" to 12" Depth |

| STRIK'R® Soil Conditioner | STRIK'R® Soil Conditioner | STRIK'R® Soil Conditioner |

| Points |

|---|

| Points |

| Points |

| Points |

| DROP ZONE™ Nutrient Placement System Single or Dual Configuration |

| DROP ZONE™ Nutrient Placement System Single or Dual Configuration |

| DROP ZONE™ Nutrient Placement System Single or Dual Configuration |

| Closing Blades |

| 1210-830 | 1210-1230 | 1210-1630 |

|---|---|---|

| 2" Chromium Carbide with Shank Wear Bar | 2" Chromium Carbide with Shank Wear Bar | 2" Chromium Carbide with Shank Wear Bar |

| 2" Rock Point with Shank Wear Bar | 2" Rock Point with Shank Wear Bar | 2" Rock Point with Shank Wear Bar |

| Adapter without NH3 Style Knives | Adapter without NH3 Style Knives | Adapter without NH3 Style Knives |

| 2" DURAKARB™ Tungsten Point with Shank Wear Bar | 2" DURAKARB™ Tungsten Point with Shank Wear Bar | 2" DURAKARB™ Tungsten Point with Shank Wear Bar |

| 3/8" Liquid - Stainless Steel & Double K® Side Plates | 3/8" Liquid - Stainless Steel & Double K® Side Plates | 3/8" Liquid - Stainless Steel & Double K® Side Plates |

| 3/8" NH3 - Stainless Steel & Double K® Side Plates | 3/8" NH3 - Stainless Steel & Double K® Side Plates | 3/8" NH3 - Stainless Steel & Double K® Side Plates |

| 1-½ Dry Tube - Stainless Steel & Double K® Side Plates | 1-½ Dry Tube - Stainless Steel & Double K® Side Plates | 1-½ Dry Tube - Stainless Steel & Double K® Side Plates |

| 16" Wavy Coulter Blades 16" Notched Reversed Disc Blades Adjustable Angle (2,10,18 degrees) | 16" Wavy Coulter Blades 16" Notched Reversed Disc Blades Adjustable Angle (2,10,18 degrees) | 16" Wavy Coulter Blades 16" Notched Reversed Disc Blades Adjustable Angle (2,10,18 degrees) |

| Recommended Operating Speed |

|---|

| Working Depth |

| Recommended Tractor Power |

| 1210-830 | 1210-1230 | 1210-1630 |

|---|---|---|

| 5 - 8 mph (8 - 13 km/h) | 5 - 8 mph (8 - 13 km/h) | 5 - 8 mph (8 - 13 km/h) |

| 6" - 12" (15.2 - 30.5 cm) | 6" - 12" (15.2 - 30.5 cm) | 6" - 12" (15.2 - 30.5 cm) |

| 23 - 30 ENG HP/row (17 - 22 kW/row) | 23 - 30 ENG HP/row (17 - 22 kW/row) | 23 - 30 ENG HP/row (17 - 22 kW/row) |

| Type de fertilisation |

|---|

| Type de fertilisation |

| 1210-830 | 1210-1230 | 1210-1630 |

|---|---|---|

| 293129;196980;196953;196989;196985;196983 | 293129;196968;196964;196954;196971;196981;196958;196952;196956;196976 | 293129;196964;196954;196981;196958;196957;196984;196973 |

| 68043 | 68043 | 68043 |

| ##blocking sensor |

|---|

| ##blocking sensor |

| 1210-830 | 1210-1230 | 1210-1630 |

|---|---|---|

| 111791 | 286422;286421;111794 | 111802 |

| 111796 | 111796 | 111796 |