Your benefits

Great Durability – Built to last

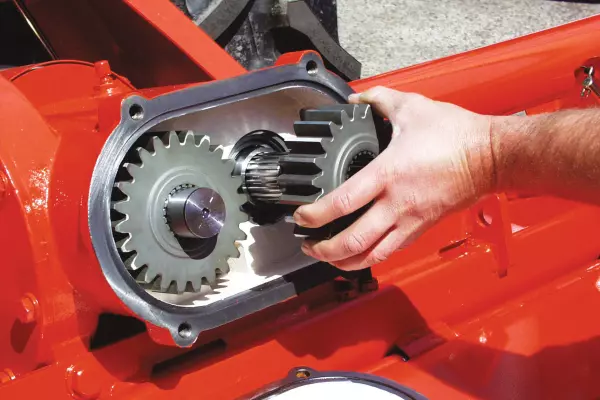

The rotor drive is constructed with case-hardened, forged steel gears. The main frame is built from a large box-section casing.

Central Gearbox

On the bigger models, the central gearbox is cast iron and set back for reduced PTO angles. A friction slip clutch is standard for protection of the drivetrain. The Duplex gearbox with two speeds is standard on the EL 92. Two additional speeds are available as optional equipment, offering the adaptation capability to various working conditions.

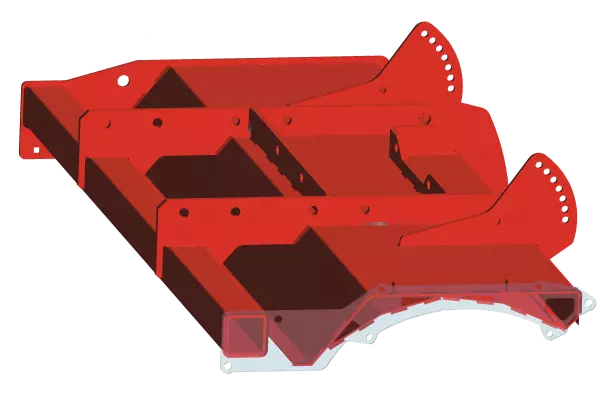

Heavy-Duty Frame

The EL 62, 82 and 92 power tillers are grouped together by a large frame providing high rigidity and exceptional endurance. The front portion is integrated with the casting, increasing the machine’s strength and giving you the potential to attach other equipment if needed.

Multiple Choices for Productivity

Skids or Wheels

On the EL 62, 82 and 92 power tiller models, working depth is controlled by using skids or wheels. These wheels are intended for work not requiring the surface to be entirely uniform. The front wheels have adjustable spacing and will roll over firm soil without leaving tracks in the worked soil.

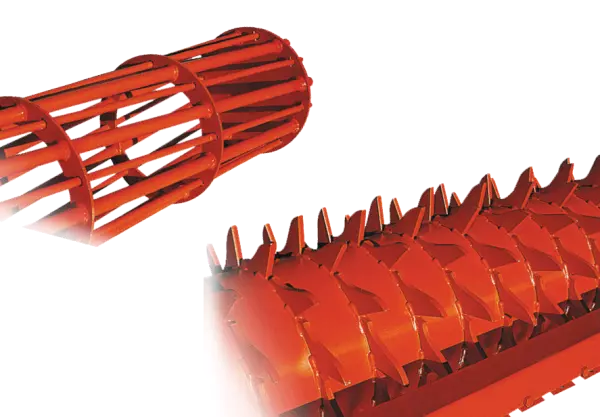

Roller Options

On select models of the EL 82 and all models of the EL 92, you can chose from either the Crumbler roller or Packer roller to help meet your soil preparation needs.

The Crumbler roller is a small 15.4” diameter roller suitable for use on dry, non-sticky soils without an integrated seed drill.

The Packer roller is 20” diameter and suitable for a wide range of soil conditions, but especially recommended for clay soils that harden while drying. The Packer roller is suitable for use with a lighter integrated drill.

The Crumbler roller is a small 15.4” diameter roller suitable for use on dry, non-sticky soils without an integrated seed drill.

The Packer roller is 20” diameter and suitable for a wide range of soil conditions, but especially recommended for clay soils that harden while drying. The Packer roller is suitable for use with a lighter integrated drill.

C-Blades

The special curved design of the KUHN tiller “C” blades has been optimized, tested and provides chopping and mixing of plant residues, aggressive entry into hard soil while requiring less horsepower and increased crumbling of soil clods. The EL Series is fitted with six blades per flange as standard for efficient crumbling.

Rear Hood

The optimized design of the rear hood is adjustable, especially valuable when changing work intensity with C-blades for optimum tillage and plant residue handling.

Providing High Work Quality and Versatility

Progressive Lateral Offset

Offset hitch capability normally allows a tiller that is narrower than the tractor to erase the tractor wheel track on its right side. Offsetting the hitch is easily accomplished by sliding the three yokes of the tiller frame. Thanks to this continuous manual offset, the machine can be adapted according to the situation to ensure stability.

Compact Design

All KUHN power tillers for vineyard and orchards are a very compact design for efficient operations in narrow rows. The small overall width-to-working width ratio of the EL 62, 82, and 92 shines through. Moreover, the rounded hood edges and skids protect plants from damage.

Specifications

SPECIFICATIONS

| Available Rotors |

|---|

| Maximum PTO power |

| Minimum PTO power |

| Central gearbox |

| PTO shaft |

| PTO protection |

| Rotor drive |

| PTO speed |

| Rotor speed |

| Rotor diameter |

| Number of flanges |

| Number of blades per flange |

| Number of blades |

| Maximum working depth |

| Depth control |

| Working depth adjustment |

| Rear hood adjustable |

| Progressive offset to the right |

| Hitch |

| Working position |

| Depth wheels |

| Road lights and signaling |

| Transport width |

| Working width |

| Approximate machine weight |

| EL 62-130 | EL 62-155 | EL 62-165 | EL 62-180 | EL 62-210 | EL 82-130 | EL 82-155 | EL 82-180 | EL 82-205 | EL 92-180 | EL 92-205 | EL 92-230 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Cultirotor | Cultirotor | Cultirotor | Cultirotor | Cultirotor | Cultirotor | Cultirotor | Cultirotor | Cultirotor | Cultirotor | Cultirotor | Cultirotor |

| 65 hp (48 kW) | 65 hp (48 kW) | 65 hp (48 kW) | 65 hp (48 kW) | 65 hp (48 kW) | 85 hp (63 kW) | 85 hp (63 kW) | 85 hp (63 kW) | 85 hp (63 kW) | 100 hp (75 kW) | 100 hp (75 kW) | 100 hp (75 kW) |

| 25 hp (19 kW) | 30 hp (22 kW) | 33 hp (24 kW) | 35 hp (26 kW) | 42 hp (31 kW) | 33 hp (24 kW) | 39 hp (29 kW) | 45 hp (33 kW) | 51 hp (38 kW) | 45 hp (33 kW) | 51 hp (38 kW) | 58 hp (45 kW) |

| Single speed | Single speed | Single speed | Single speed | Single speed | Single-speed | Single-speed | Single-speed | Single-speed | Two-speed | Two-speed | Two-speed |

| Standard 1 3/8'' - 6-spline | Standard 1 3/8'' - 6-spline | Standard 1 3/8'' - 6-spline | Standard 1 3/8'' - 6-spline | Standard 1 3/8'' - 6-spline | Standard 1 3/8'' - 6-spline | Standard 1 3/8'' - 6-spline | Standard 1 3/8'' - 6-spline | Standard 1 3/8'' - 6-spline | Standard 1 3/8'' - 6-spline | Standard 1 3/8'' - 6-spline | Standard 1 3/8'' - 6-spline |

| Slip clutch | Slip clutch | Slip clutch | Slip clutch | Slip clutch | Slip clutch | Slip clutch | Slip clutch | Slip clutch | Slip clutch | Slip clutch | Slip clutch |

| Forged steel gears | Forged steel gears | Forged steel gears | Forged steel gears | Forged steel gears | Forged steel gears | Forged steel gears | Forged steel gears | Forged steel gears | Forged steel gears | Forged steel gears | Forged steel gears |

| 540 rpm | 540 rpm | 540 rpm | 540 rpm | 540 rpm | 540 rpm | 540 rpm | 540 rpm | 540 rpm | 540 rpm | 540 rpm | 540 rpm |

| 224 rpm | 224 rpm | 224 rpm | 224 rpm | 224 rpm | 212 rpm | 212 rpm | 212 rpm | 212 rpm | 194 and 230 rpm | 194 and 230 rpm | 194 and 230 rpm |

| 18" (45.7 cm) | 18" (45.7 cm) | 18" (45.7 cm) | 18" (45.7 cm) | 18" (45.7 cm) | 21" (53 cm) | 21" (53 cm) | 21" (53 cm) | 21" (53 cm) | 21" (53 cm) | 21" (53 cm) | 21" (53 cm) |

| 5 | 6 | 6 | 7 | 9 | 5 | 6 | 7 | 8 | 7 | 8 | 9 |

| 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

| 30 | 36 | 36 | 42 | 54 | 30 | 36 | 42 | 48 | 42 | 48 | 54 |

| 7" (17.8 cm) | 7" (17.8 cm) | 7" (17.8 cm) | 7" (17.8 cm) | 7" (17.8 cm) | 9" (23 cm) | 9" (23 cm) | 9" (23 cm) | 9" (23 cm) | 9" (23 cm) | 9" (23 cm) | 9" (23 cm) |

| Depth wheels | Depth wheels | Depth wheels | Depth wheels | Depth wheels | Depth wheels | Depth wheels | Depth wheels | Depth wheels | Depth wheels | Depth wheels | Depth wheels |

| Manual | Manual | Manual | Manual | Manual | Manual | Manual | Manual | Manual | Manual | Manual | Manual |

| 7 pin positions | 7 pin positions | 7 pin positions | 7 pin positions | 7 pin positions | 7 pin positions | 7 pin positions | 7 pin positions | 7 pin positions | 7 pin positions | 7 pin positions | 7 pin positions |

| 8" (20.3 cm) | 8" (20.3 cm) | 8" (20.3 cm) | 8" (20.3 cm) | 8" (20.3 cm) | 8" (20 cm) | 8" (20 cm) | 8" (20 cm) | - | 4" (10 cm) | - | - |

| Cat. 1, 1N, and 2 | Cat. 1, 1N, and 2 | Cat. 1, 1N, and 2 | Cat. 1, 1N, and 2 | Cat. 1, 1N, and 2 | Cat. 1, 1N and 2 | Cat. 1, 1N and 2 | Cat. 1, 1N and 2 | Cat. 1 & 2 | Cat. 1 and 2 | Cat. 1 and 2 | Cat. 1 and 2 |

| Rigid | Rigid | Rigid | Rigid | Rigid | Rigid | Rigid | Rigid | Rigid | Rigid | Rigid | Rigid |

| Standard | Standard | Standard | Standard | Standard | Standard | Standard | Standard | Standard | Standard | Standard | Standard |

| - | - | Standard - reflectors only | Standard - reflectors only | Standard - reflectors only | Standard - reflectors only | Standard - reflectors only | |||||

| 55" (1.4 m) | 65" (1.7 m) | 69" (1.8 m) | 74" (1.9 m) | 87" (2.2 m) | 66" (1.7 m) | 76" (1.9 m) | 85" (2.2 m) | 98" (2.5 m) | 85" (2.2 m) | 98" (2.5 m) | 109" (2.8 m) |

| 50" (1.3 m) | 60" (1.5 m) | 65" (1.7 m) | 70" (1.8 m) | 83" (2.1 m) | 51" (1.3 m) | 61" (1.6 m) | 71" (1.8 m) | 81" (2.1 m) | 71" (1.8 m) | 81" (2.1 m) | 91" (2.3 m) |

| 650 lbs (295 kg) | 729 lbs (331 kg) | 793 lbs (360 kg) | 808 lbs (367 kg) | 925 lbs (420 kg) | 870 lbs (395 kg) | 948 lbs (430 kg) | 1,025 lbs (465 kg) | 1,124 - 1,697 lbs (510 - 770 kg) | 1,157 lbs (525 kg) | 1,256 - 1,829 lbs (570 - 830 kg) | 1,333 - 1,973 lbs (605 - 895 kg) |

Media

Customer Spotlight: EL 62/82/92

![Larry Kalugin - KUHN VKD 155 shredder, and EL 82 power tiller]()

Larry Kalugin Caneberry Farmer

"My wife and I run a caneberry farm in Woodburn, Ore. We own several pieces of KUHN equipment, including a pair of VKD 155 shredders, a pair of EL 82 power tillers and an MDS 62 fertilizer spreader. Over the years we have used other brands of equipment, but find ourselves continually coming back to KUHN. The tillers in particular are by far the smoothest and quietest we've ever used."